By Lou CoveyEditorial Director

This is our second part on our series on the weaknesses of alternative power. In this installment, we look at the core of our generation technology, the turbine.

Entering into an evaluation of turbine technology we need to understand how important the technology is to production of electricity. What is going on in California is valuable to that understanding.

Governor Jerry Brown recently signed a law that says 33 percent of it power production must come from renewable sources, primarily through solar technology. The state has been lauded recently for advances in this effort and by 2014 total production was 20 percent of the total from renewables. However, that does not mean that 20 percent of the energy the state consumes is from renewables. In reality, California only produces 67 percent of all the energy it consumes, down from 90 percent in 1990.

California is increasingly dependent on power generation from other states, like Utah and Idaho, where the bulk of energy is produced by facilities that burn natural gas and coal to produce steam that drives their turbines. As a result, the power consumed in California is actually dirtier than it was 20 years ago. How this happens is an interesting shell game.

Let’s say you have a coal-fired generation plant producing 1 GW or power every day, 24 hours a day. This power can be used anywhere because the technology is easily distributed through the entire network, but it is “dirty” power because it producing carbon dioxide. You want to clean up the environment so you build a 500 MW solar farm to produce clean, renewable energy. But that farm only produces power, at best, 6 hours a day and can only be distributed in a very small area of the state. And then you shut down the coal-fired plant.

That gives you a net loss of 500 MW so you contract with a Utah utility to buy their excess power to make up the difference, and you have to actually buy more than that 500 MW because you also have to provide power during peak usage, that begins after 4 p.m., when the solar panels go off line. So the carbon dioxide produced by the Utah facility is equivalent to what was produced by your shuttered plant in California.

Here’s the good news, though, by shuttering the coal-fired plant, you have now increased the net amount of energy you produced by renewables by a 1.5 GWs even though you are producing 500 MW less. You now issue a press release saying you have dramatically increased the percentage of renewable power produced by the state… even though you’ve really done nothing for the environment. In fact, you may have made it worse.

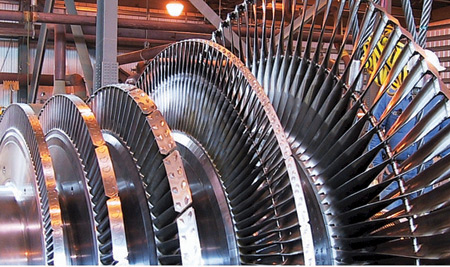

Steam turbines have been generating electric power since the early 1900s. In 1903, Commonwealth Edison opened Fisk Generating Station in Chicago, using 32 Babcock and Wilcox boilers driving several GE Curtis turbines, at 5000 and 9000 kilowatts each, the largest turbine-generators in the world at that time. Almost all electric power generation, from the time of the Fisk Station to the present, is based on steam driven turbine-generators. The Fisk turbine was a single stage, with one set of blades, and could achieve a maximum theoretical efficiency of 33 percent but achieved much lower numbers.

Efficiency is determined by the amount of power converted from the steam to usable electricity. Turbine efficiency is determined by the number of blades, their design, the amount of turbulence behind each set of blades, friction and steam temperature. Over the years turbine efficiency has been improved to as much as 40 percent improved as additional stages were added. Again there are limitations even today are based on the quality of the water (seawater, alkaline water, etc.) and the quality of the blades.

However, turbines don’t produce electricity as soon as you flip a switch. The huge and expensive turbines must be gradually spun up (using electrical or mechanical power) before the steam can be gradually applied to heat up and expand the blades to operational levels. This process can take several hours. Utilities have to predict what the demand will be a half day before spinning up the turbines so when the solar arrays go off line at 4-5 p.m. the turbines are generating power enough to make up for the loss. Utilities are producing as much as 110 percent of maximum power from just after noon on day one until demand drops after 8 p.m. That means a significant amount of the power produced during solar peak production is actually wasted energy.

Whether the turbines are driven by steam, hydro or gas, the blades of the turbine need regular replacement and repair, depending on the quality of the working fluid or gas. Heat, contaminants and turbulence can weaken and warp the blades in a relatively short time requiring that the power plant be taken down in part or altogether. There are constant design advances to lessen downtime and increase output, but turbine technology remains inefficient and costly. As a result many utilities, like Pacific Gas and Electric, are divesting themselves of power generation to concentrate on power distribution alone. As more third-party companies take over generation, our ability to maintain a steady flow of power is endangered. If one company fails economically, will we have the ability to make up for the loss of their production?